Wise System

File typepdf

Size170.27 KB

Download

See online

Fill in the fields correctly

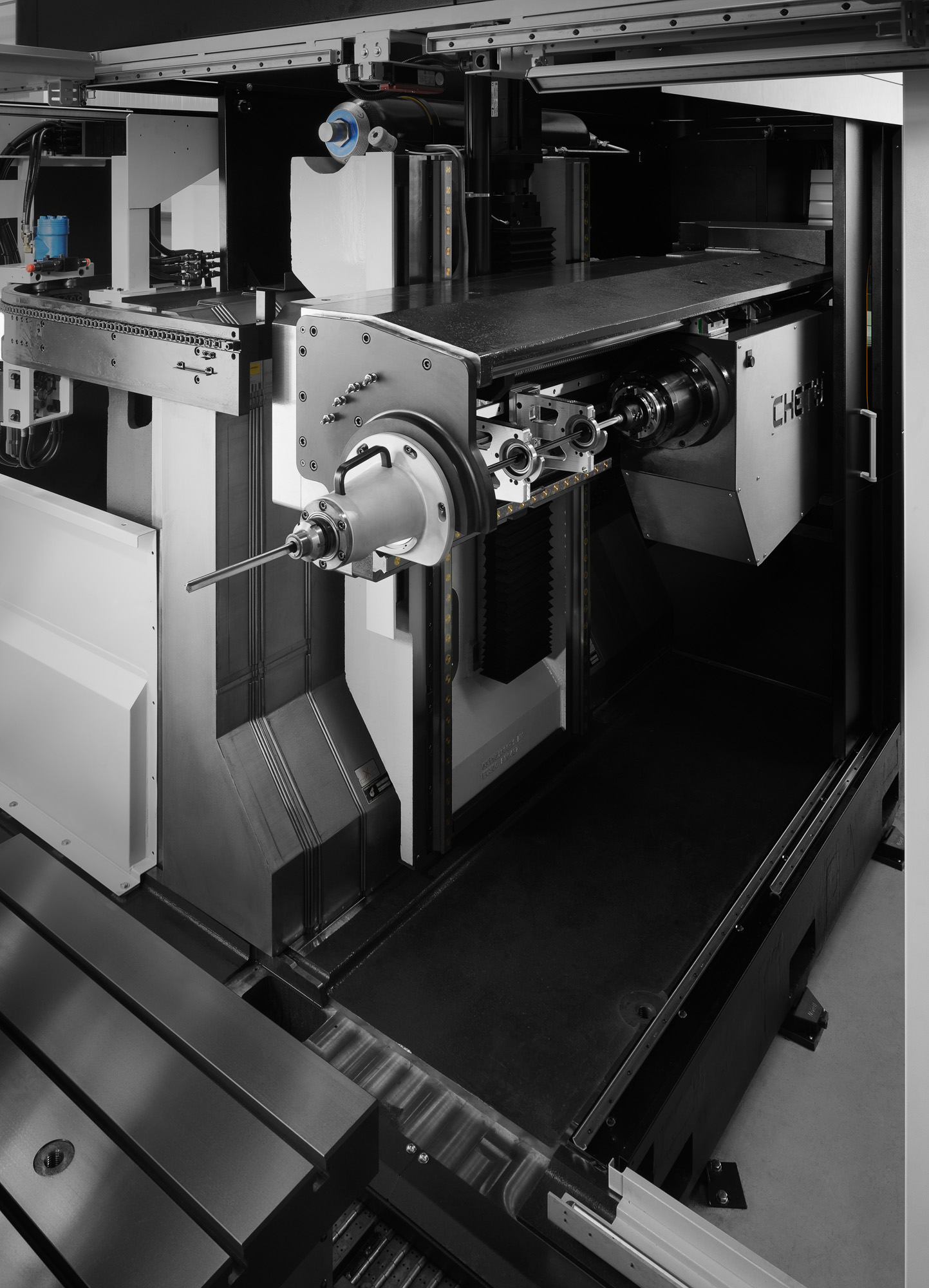

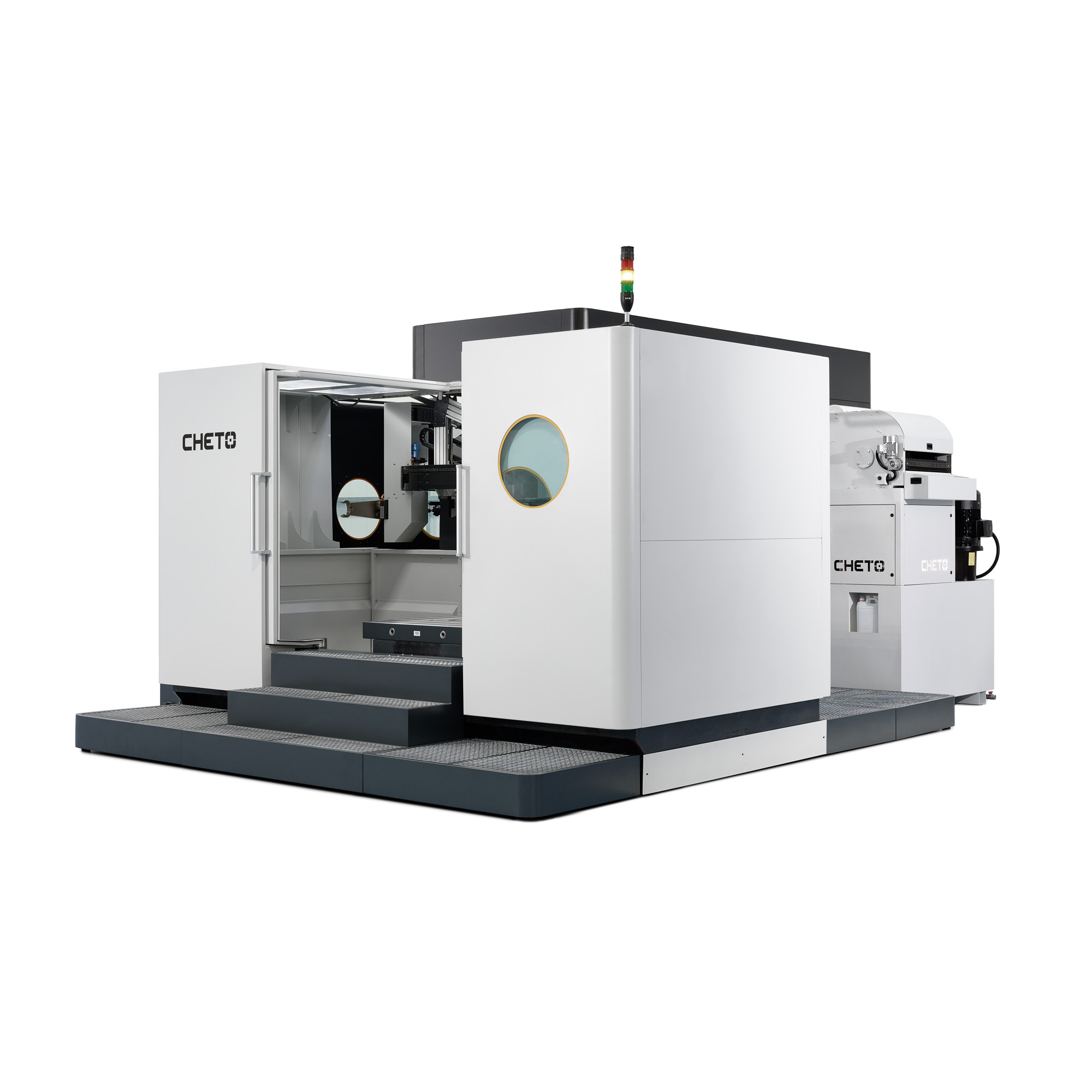

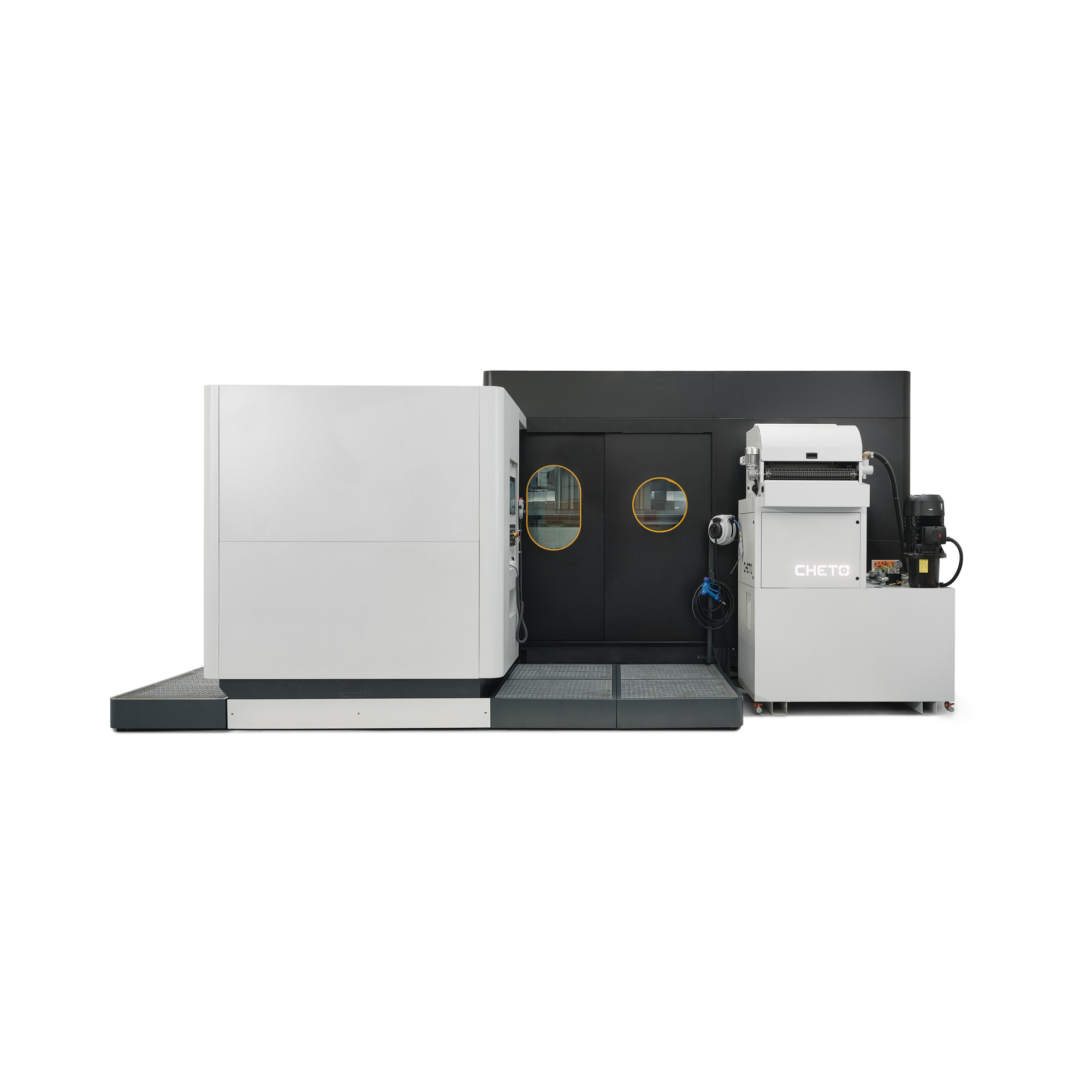

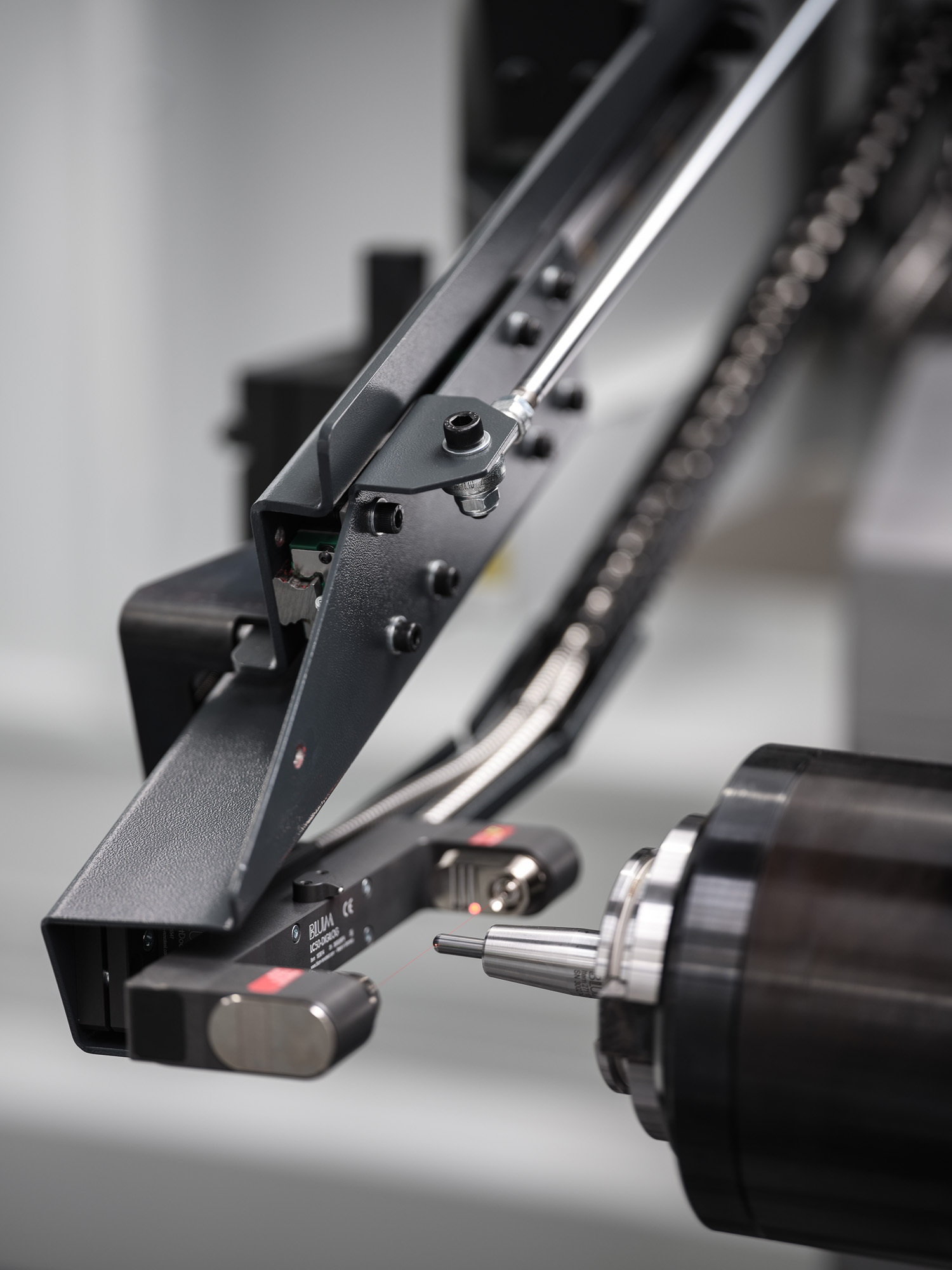

CNC DEEP HOLE DRILLING WITH MILLING

GPS. 40°48'00.5

+351 256 247 970